In today’s digital era, our gadgets are constantly exposed to dust, scratches, moisture, and wear from everyday use. Whether it’s smartphones, tablets, laptops, or LED screens, keeping them in pristine condition is a top priority. That’s where self-adhesive protection films step in with revolutionary upgrades!

Let’s explore the latest innovations in protective films for electronics, and why they are a must-have in both consumer and industrial applications.

🔍 What Are Self-Adhesive Protection Films for Electronics?

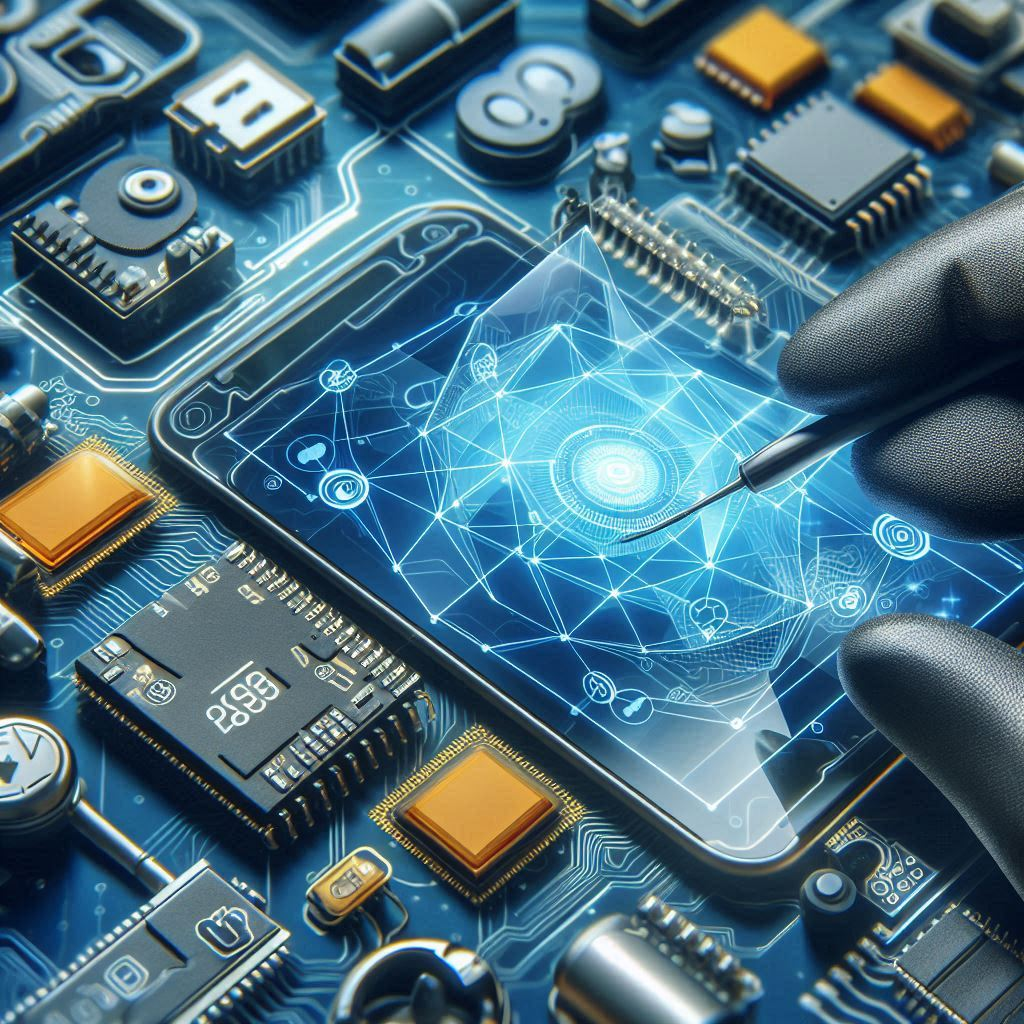

Self-adhesive protection films are ultra-thin, flexible sheets applied to electronic surfaces to shield them from physical and environmental damage. These films use pressure-sensitive adhesives, making them easy to apply and remove without leaving sticky residues.

Whether you’re looking for a temporary surface protection or a longer-term solution, these films provide the ideal balance of convenience, durability, and clarity.

🌟 Key Innovations in Electronic Protection Films

1️⃣ Nano-Coating Technology

Modern protective films now use nano-coating for enhanced strength and durability. These coatings offer:

- Hydrophobic & oleophobic properties (resists water and fingerprints 💧)

- Anti-smudge and easy-to-clean surfaces

- Scratch resistance with up to 9H hardness

This is a game-changer for electronics screen protection films.

2️⃣ Anti-Glare & Anti-Reflective Features 😎

With increasing screen time, eye comfort is crucial. The latest films feature anti-glare layers that reduce light reflection and improve visibility in bright environments.

Perfect for:

✔️ Tablets

✔️ Touchscreen kiosks

✔️ Outdoor display screens

3️⃣ Flexible and Ultra-Thin Films

Gone are the days of thick, rigid protectors. Today’s films are:

- Less than 0.1mm thin

- Super flexible and adaptable to curved surfaces

- Ideal for edge-to-edge devices

This innovation is especially useful for smartphones with curved displays and foldable devices.

4️⃣ Electrostatic Adhesion Technology ⚡

Some films now use electrostatic adhesion instead of glue-based adhesives. This offers:

- Bubble-free application

- Zero adhesive residue

- Reusability in certain cases

Great for delicate electronics and high-end displays where appearance matters.

5️⃣ UV-Resistant and Heat-Stable Films ☀️

Long-term exposure to sunlight and heat can degrade electronics. The latest UV-resistant protective films for outdoor use shield electronic devices from harmful rays and high temperatures, ensuring longevity.

Why These Innovations Matter

In industries like automotive, medical electronics, and consumer tech, the demand for durable and custom surface protection film manufacturers has skyrocketed. These innovations support:

- Longer device lifespan

- Reduced repair & replacement costs

- Enhanced user experience

- Better resale value for electronic devices

🏭 Industry-Specific Applications

🔌 Consumer Electronics – Smartphones, tablets, laptops

🔬 Medical Equipment – Touch panels, monitors

🚘 Automotive Displays – GPS, infotainment systems

📦 Packaging Protection Film Suppliers – Protect devices during shipping

Construction Surface Protection Solutions – Safeguard control panels at sites

🏁 Final Thoughts

From anti-glare enhancements to nano-coated scratch resistance, today’s self-adhesive protection films are engineered to deliver maximum performance for modern electronics. 📱💡

Whether you’re a tech-savvy consumer or a manufacturer seeking reliable protection, investing in the latest protective film for surfaces is a smart move toward durability and device integrity.